Which Material Is Useful In Aerospace Industry?

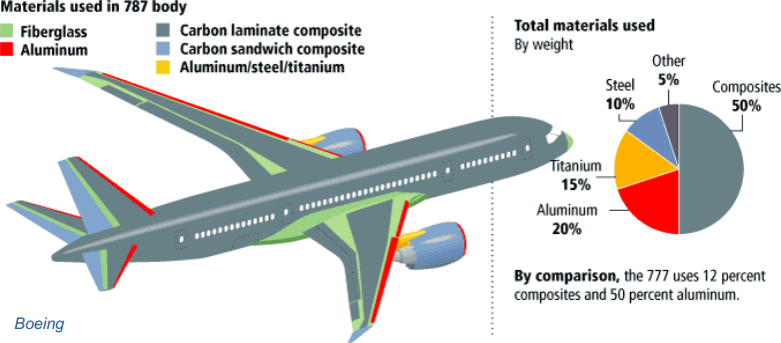

The aerospace industry utilizes a variety of materials to construct aircraft and spacecraft. These materials must be lightweight, durable, and highly resistant to corrosion and heat. Common materials used in aerospace include aluminum alloys, titanium alloys, and composite materials. Aluminum alloys are lightweight and relatively inexpensive when compared to other materials, making them a popular choice for aircraft structures. Titanium alloys are extremely strong and resistant to corrosion, and are often used in aircraft engines and other components that require high strength and durability. Composite materials, such as carbon fiber, are also becoming more popular in the aerospace industry due to their combination of light weight and strength.

Introduction

Welcome to the blog section of our website! Here you can find a variety of topics, ranging from lifestyle and fashion to business and tech, all written by our experienced panel of contributors. Our blog posts offer a unique perspective on the latest trends and topics, providing readers with valuable insights and useful advice. Whether you’re looking for a quick read or a comprehensive guide, you’ll find the content you need here. So what are you waiting for? Dive in and explore the world of our blog section.

Common Aerospace Materials

Aerospace materials are materials used in the construction of aircraft, spacecraft, missiles and other related structures and components. They must meet stringent requirements for strength, weight, durability, resistance to corrosion and temperature, and other factors. Common aerospace materials include aluminum alloys, titanium alloys, steel alloys, composites and polymers. Each of these materials has its own unique properties and advantages, allowing engineers to design aircraft and spacecraft that are both strong and light. With advances in material technology, aerospace engineers are continually pushing the boundaries of what is possible with these materials.

Manufacturing Processes for Aerospace Materials

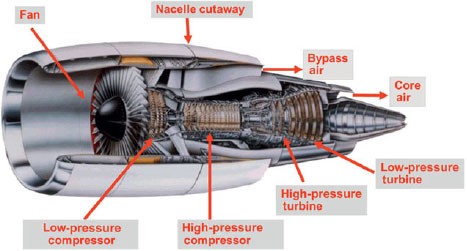

Aerospace materials are an integral part of the aerospace industry, used for a variety of applications from aircraft manufacturing to engine components. The manufacturing process for these materials requires specialized tools and techniques, as the end product must meet strict safety and performance standards. From the selection of the raw material to the assembly of the final components, the manufacturing process for aerospace materials involves a number of steps. These steps include cutting, forming, welding, heat treating, and finishing. With the help of the latest technology, such as advanced cutting, welding, and machining tools, manufacturers are able to design and produce components that meet the highest standards of reliability and performance.

Advantages of Aerospace Materials

Aerospace materials are essential for the construction of aircraft, satellites, and spacecraft, and their advantages are numerous. Aerospace materials are strong yet lightweight, durable, and capable of withstanding extreme temperatures and pressure changes. Furthermore, they can be designed to resist damage from vibration, shock, and corrosion, and are often chosen for their specific properties and features. This makes them ideal for use in a variety of space-related applications, including spacecraft, aircraft, and missiles. Aerospace materials are also non-polluting and easy to manufacture, making them cost-efficient and environmentally friendly. With their superior strength and durability, aerospace materials are a valuable resource for the aerospace industry and have numerous advantages.

Challenges of Aerospace Materials

Aerospace materials are the cutting-edge of technology. They are designed to withstand extremely high temperatures, pressures, and speeds. However, as with any advanced technology, aerospace materials come with their own unique challenges. From the need to make materials lighter and more durable, to the need to make materials more cost-effective and environmentally friendly, aerospace materials present an ever-evolving set of challenges. As aerospace technology continues to develop and evolve, so too do the challenges associated with aerospace materials. It is up to engineers and scientists to develop innovative solutions to these challenges, so that aerospace technology can reach its full potential.

Conclusion

The blog section is a valuable resource for anyone looking to gain insight and knowledge on a variety of topics. It offers a unique platform to learn from the experiences of others and explore new ideas. It can be a great way to stay up-to-date on industry trends, connect with like-minded people, and share your thoughts and opinions. The blog section can be a useful tool for businesses to build a presence online and engage with their customers in meaningful ways. Ultimately, the blog section is a powerful platform that can be used to educate, inform, and entertain readers around the world.

FAQs About the Which Material Is Useful In Aerospace Industry?

Q1. What materials are used in aerospace engineering?

A1. Aerospace engineering typically utilizes materials such as aluminum, titanium, composites, and various alloys. These materials are chosen for their strength, weight, and durability in extreme environments.

Q2. What is the most important material used in aerospace engineering?

A2. Titanium is often considered the most important material used in aerospace engineering because of its strength, light weight, and corrosion resistance.

Q3. Are there any other materials used in aerospace engineering?

A3. Yes, composites and various alloys are also commonly used in aerospace engineering. Composites are used for their strength and light weight, while alloys are chosen for their durability and resistance to extreme temperatures.

Conclusion

The aerospace industry relies on a wide range of materials for its products. From metals like steel and aluminum to composites like carbon fiber and Kevlar, the aerospace industry utilizes these materials in various ways to ensure that the aircraft it produces can handle the rigors of flight. Each of these materials offers its own unique set of advantages, making them all essential for the aerospace industry to create safe, high-performing aircraft.