What Parts In Car Can Be Made Of Carbon Fiber?

Carbon fiber is a material that has become increasingly popular in the automotive industry. It is a strong, lightweight material that has higher strength-to-weight ratios than steel or aluminum. Carbon fiber has become a popular choice for many parts in cars, from chassis components to body panels. It is used in many different types of vehicles, from high-performance sports cars to luxury sedans. Carbon fiber makes cars lighter and more fuel-efficient, while also making them stronger and more durable. By using carbon fiber, car manufacturers can reduce the weight of their vehicles and improve their performance.

What is Carbon Fiber?

Carbon fiber is a revolutionary material that is increasingly being used in a wide range of industries. It is one of the strongest and lightest materials available, making it an ideal choice for a variety of applications. Carbon fiber is composed of thin strands of carbon atoms that are bonded together in a crystalline structure. This structure gives it its strength and stiffness, while still being lightweight. Carbon fiber is incredibly strong, yet it is five times lighter than steel. It can also be shaped into a variety of forms, making it a versatile material. Carbon fiber is used in various industries such as aerospace, automotive, sports equipment, and engineering. Its strength-to-weight ratio makes it an ideal choice for applications that require a lightweight yet strong material. Carbon fiber is a revolutionary material that is revolutionizing the way we build and design products.

Advantages of Carbon Fiber in Automotive Applications

Carbon fiber is an excellent material choice for automotive applications. It is lightweight, strong, and durable, making it ideal for use in cars, trucks, and other vehicles. Carbon fiber also offers superior heat and vibration dampening, which helps to reduce noise and vibration within the vehicle. Additionally, its excellent thermal and electrical conductivity makes it ideal for use in electrical components such as wiring and batteries. Finally, carbon fiber is highly resistant to corrosion and other environmental factors, making it a great choice for exterior components of the vehicle. This makes for a vehicle that is lighter, faster, and more reliable. With carbon fiber, the automotive industry has the potential to revolutionize the way we travel.

Types of Carbon Fiber Used in Automotive Applications

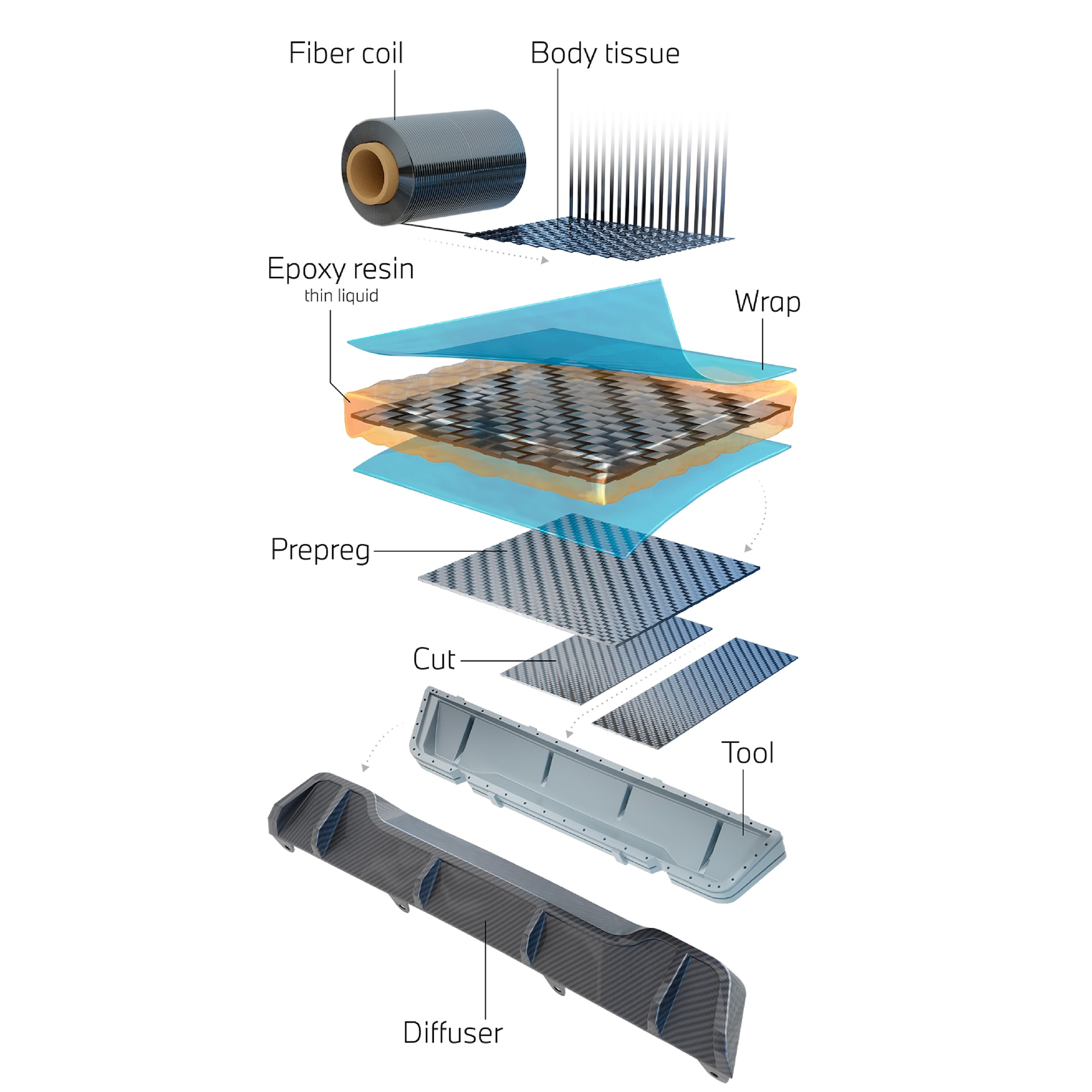

Carbon fiber is a popular choice for the automotive industry as it is lightweight and strong. It can be used in a variety of applications, from improving the aerodynamics of a car, to increasing its structural integrity. In automotive applications, there are two main types of carbon fiber: pre-impregnated (prepreg) carbon fiber and woven carbon fiber. Prepreg carbon fiber is pre-treated with a resin that allows it to be easily molded and shaped into the desired shape. Woven carbon fiber is stronger and more durable than prepreg, as it is a heavier, more rigid material, making it ideal for structural components such as frames and body panels. Both types of carbon fiber are excellent for automotive applications, and the choice of which type to use depends on the intended application.

Examples of Carbon Fiber Parts in Automotive Applications

The automotive industry is constantly pushing the boundaries of design, efficiency, and performance. Carbon fiber parts are becoming increasingly popular in the automotive world, with their lightweight, strong, and durable properties. Carbon fiber parts provide superior strength to weight ratios compared to traditional materials like steel and aluminum, allowing for more efficient and powerful engines, lighter and more agile cars, and a more dynamic driving experience. Examples of carbon fiber parts commonly used in automotive applications include body panels, spoilers, wheel rims, exhaust systems, suspension components, and interior trim. Carbon fiber parts can also be used to reduce noise and vibration, improve aerodynamics, and reduce overall vehicle weight. By utilizing carbon fiber parts, automotive engineers can design cars that are faster, safer, and more efficient than ever before.

Challenges Associated with Carbon Fiber Automotive Parts

Carbon fiber automotive parts are becoming increasingly popular among car enthusiasts and manufacturers, as they offer a strong, lightweight alternative to metal components. However, there are certain challenges associated with using carbon fiber which should be considered when making a decision on whether to use them. These include the cost of the materials, the complexity of manufacturing, the risk of damage from collisions, and the difficulty in recycling or disposing of them. Additionally, carbon fiber components can be sensitive to heat, and may require additional protection from extreme temperatures. Despite these challenges, carbon fiber automotive parts can provide an attractive and durable solution for those looking to improve the performance and appearance of their vehicles.

Future of Carbon Fiber in the Automotive Industry

The automotive industry is rapidly evolving and the use of carbon fiber is becoming more popular. Carbon fiber is an incredibly strong and lightweight material that is revolutionizing the way automobiles are built. It is a key component of a vehicle’s frame and body, and provides superior strength, durability, and performance compared to traditional materials. The benefits of using carbon fiber in the automotive industry are numerous, including decreased weight, improved fuel efficiency, increased power, improved safety, and reduced emissions. As the demand for lighter and stronger vehicles continues to rise, the use of carbon fiber in automotive construction will become increasingly important. In the near future, it is likely that carbon fiber will be widely used in the automotive industry and will play a major role in the design and construction of future vehicles.

FAQs About the What Parts In Car Can Be Made Of Carbon Fiber?

1. What are the benefits of using carbon fiber parts in a car?

– Carbon fiber parts in a car are lightweight and strong, improving performance as well as fuel efficiency. They are also resistant to corrosion and temperature extremes, so they last longer than traditional materials.

2. Are carbon fiber parts expensive?

– Carbon fiber parts can be more expensive than traditional materials, but they also last longer and provide better performance. As the technology continues to improve and become more widely available, the cost of carbon fiber parts is likely to decrease.

3. Can carbon fiber parts be replaced if they become damaged?

– In some cases, carbon fiber parts can be replaced. However, the process is often complicated and can be costly. It is important to consult a professional before attempting to replace a carbon fiber part.

Conclusion

In conclusion, using carbon fiber to make parts in cars is a great option because it is lightweight, strong, and durable. Carbon fiber is also resistant to corrosion and is able to withstand extreme temperatures. It is also resistant to wear and tear, which makes it an ideal material for automotive parts. Furthermore, its low cost and easy availability make it more cost effective compared to other materials. It is clear that carbon fiber has many advantages and continues to gain popularity in the automotive industry.