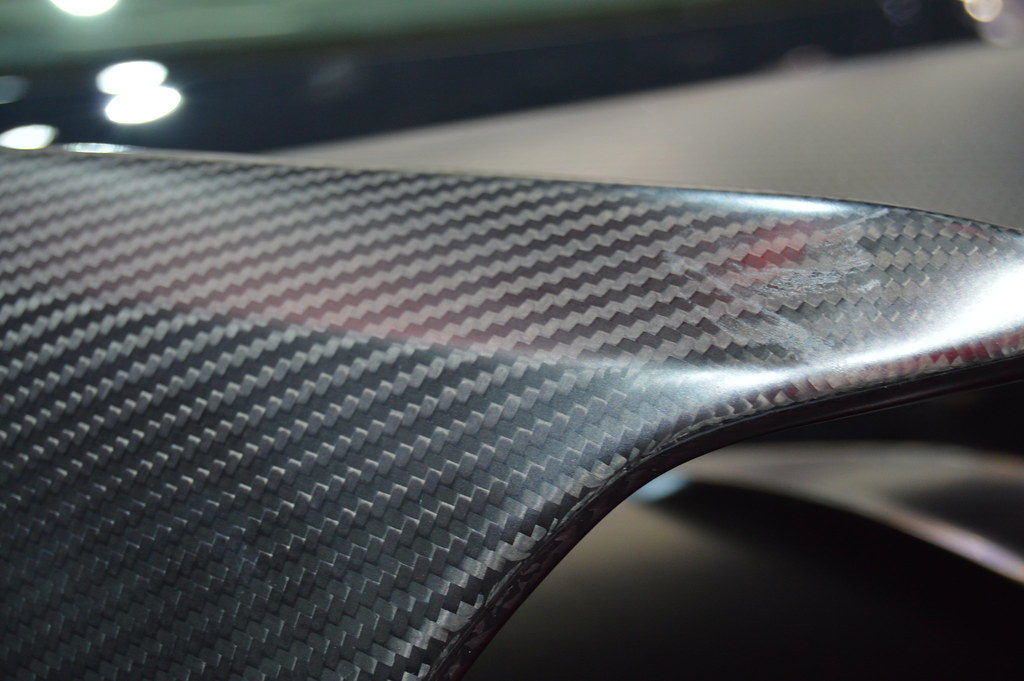

How Strong Are Carbon Fiber Car Parts?

Carbon fiber car parts are becoming increasingly popular due to their strength and lightweight properties. The strength of carbon fiber car parts is often compared to steel, however, it is much lighter in weight. Carbon fiber is a composite material made from woven strands of carbon that are bonded together and formed into a reinforced shape. Its strength is due to the strong bonds between the carbon strands that make up the material. Carbon fiber car parts are used in vehicles for a variety of reasons including strength, durability, and weight reduction. Carbon fiber parts are also resistant to corrosion and can be used in a variety of temperatures. Carbon fiber car parts are more expensive than traditional steel parts, but the advantages of using them are worth the investment.

What are Carbon Fiber Car Parts?

Carbon fiber car parts are the pinnacle of modern engineering and design. These ultra-lightweight components are made from a combination of carbon and other materials, providing superior strength, stiffness, and durability when compared to traditional metal parts. Carbon fiber car parts are often used to enhance the performance and aesthetics of a car, such as improved aerodynamics, weight reduction, and improved styling. While Carbon Fiber car parts can be expensive, they are a great investment for any car enthusiast or racer looking for the best performance available.

Advantages of Carbon Fiber Car Parts

Carbon fiber car parts offer a number of advantages over traditional metal vehicle components. These include increased strength and durability, improved fuel economy, reduced weight, and increased corrosion resistance. Carbon fiber car parts are also much lighter than their metal counterparts, which means they can improve the performance of the car and reduce the amount of fuel used. Additionally, carbon fiber car parts are more resistant to corrosion, which can save car owners money on expensive repairs down the line. Carbon fiber car parts also tend to look more stylish and modern, making them an attractive choice for many car owners. All in all, carbon fiber car parts offer numerous advantages for car owners, making them a great choice for any vehicle.

Disadvantages of Carbon Fiber Car Parts

Carbon fiber car parts may appear to be the ideal solution for a lightweight, strong and durable part, however, there are some drawbacks. Firstly, carbon fiber parts can be expensive because of its complex manufacturing process. Secondly, it has a much shorter lifespan compared to traditional metal or fiberglass parts, meaning it may need to be replaced more often. Additionally, carbon fiber parts are more difficult to repair or replace due to their fragile nature and the fact that they cannot be welded. Finally, carbon fiber parts can be difficult to paint, making it difficult to customize the look of a car. Despite these drawbacks, carbon fiber parts can still be a great addition to any car, providing an impressive level of strength and performance.

The Strength of Carbon Fiber Car Parts

Carbon fiber car parts are becoming increasingly popular in the automotive industry due to their superior strength and lightweight. These parts provide greater stability and control, and are also more resistant to corrosion and wear, making them a great choice for racers and everyday drivers alike. Carbon fiber car parts are made from carbon fibers woven together and embedded in a resin matrix, creating a strong, yet lightweight material that can be formed into virtually any shape. This makes them perfect for body panels, hoods, and other components that need to be both strong and lightweight. The higher strength-to-weight ratio of carbon fiber car parts also makes them an ideal choice for performance-oriented builds, as they allow for greater power and speed without sacrificing structural integrity.

How Carbon Fiber Car Parts are Manufactured

Carbon fiber car parts are manufactured by weaving thin strands of carbon fiber into fabric-like sheets. These sheets are then cut, shaped, and bonded together with resin to form the desired car part. The use of carbon fiber has become increasingly popular in the automotive industry due to its light weight, strength, and durability. Carbon fiber car parts are also highly resistant to corrosion and can even be painted to match the original color of the car. The manufacturing process for carbon fiber car parts is a complex one, but the end result is a lightweight, strong, and aesthetically pleasing part that is sure to last for years to come.

Cost Considerations of Carbon Fiber Car Parts

Carbon fiber car parts are becoming increasingly popular for a variety of reasons – they are lightweight, durable, and aesthetically pleasing. But, as with any modern innovation, there are cost considerations to be taken into account. Carbon fiber parts require a greater upfront investment than traditional metal counterparts, but the long-term savings are often worth it. Carbon fiber parts last longer, require less maintenance, and can increase fuel economy or performance due to their light weight. Additionally, they can improve the overall value of a car, as they are widely viewed as a luxury item. While the initial cost of carbon fiber car parts can be intimidating, the overall benefits may make it an investment worth considering.

FAQs About the How Strong Are Carbon Fiber Car Parts?

Q1. What is carbon fiber?

A1. Carbon fiber is a lightweight, strong material made from strands of carbon atoms. It is often used to make strong, durable car parts such as body panels, spoilers, and chassis components.

Q2. How strong are carbon fiber car parts compared to steel parts?

A2. Carbon fiber car parts are much lighter than steel parts but can be just as strong. In some cases, carbon fiber parts can be stronger than steel parts, depending on the design and application.

Q3. Are carbon fiber car parts more expensive than steel parts?

A3. Generally speaking, carbon fiber car parts can be more expensive than steel parts due to the cost of materials and production. However, their lighter weight can provide a performance advantage that may be worth the additional cost.

Conclusion

Carbon fiber car parts are incredibly strong and durable, making them a great option for car owners who want to upgrade their vehicles. Carbon fiber is lightweight, corrosion-resistant, and strong enough to handle the toughest conditions. Additionally, carbon fiber car parts are relatively affordable, making them a great option for those on a budget. With its many benefits, it’s no wonder why carbon fiber car parts have become so popular amongst car owners.